DECCAN MECHANICAL AND CHEMICAL INDS.P.LTD.

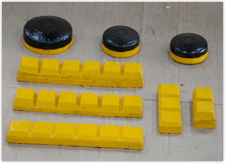

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to DECCAN MECHANICAL AND CHEMICAL INDS.P.LTD.

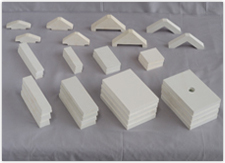

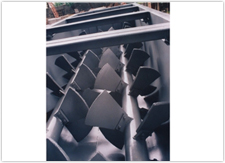

Cast Basalt Liners

After selective quarrying the rock is melted at a temperature of around 1500 degree C and cast into molds or spun into cylinders. The castings so produced are then subjected to heat treatment cycles in special kilns to produce re-crystallized basalt. The product thus produced inherits inertness of parent materials. Its microcrystalline, non-porous texture being denser and more homogenous than raw basalt, it acquires exceptionally high abrasion resistance.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.